What is S&OP?

Sales and operations planning, or S&OP, is essentially an integrated business planning process, though some consider the latter more holistic and inclusive. In this blog post, we answer questions including what is S&OP, what it is used for and how it provides value to organizations.

What is S&OP?

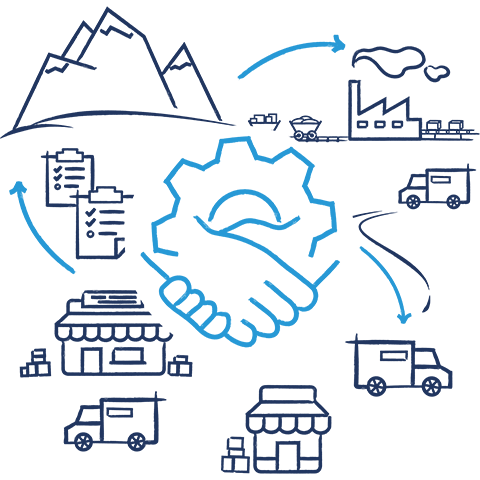

S&OP is a process by which sales plans and business goals get aligned with all other functions in an organization and vice versa. Sales and operations planning can be understood as an umbrella term for integrated business planning from sales plans to production plans to inventory plans and more, depending on organizational structure. While some argue that financial planning and analysis (FP&A) isn’t part of S&OP, others beg to differ, citing the importance of alignment in planning throughout the organization. This is also where integrated planning and S&OP most often intersect.

The integrated process of S&OP is one of the most important tasks for organizations in manufacturing. It helps business leaders with decisions regarding resource allocation by providing crucial insights from throughout the organization. Especially in a globalized world, where often production plants can be located in several different countries, a consistent aggregated data foundation is key for accurate sales and operations planning. If the processes are properly coordinated and integrated, the organization will always have an accurate overview of required resources for production to meet demand.

As a result, purchasing staff also know exactly when which parts need to be available and can align their planning accordingly. In this way, harmonized S&OP processes lead to increased profitability for the company.

The origins of S&OP

Together with Walter Goddard, Richard Ling coined the term S&OP in their 1988 book “Orchestrating Success: Improve Control of the Business with Sales and Operations Planning.” Since then, the concept has been developed further by the original authors as well as others. It is generally described as a five-step process that includes:

- collection and preparation of data,

- demand planning,

- supply planning,

- plan consolidation for demand and supply balancing, and

- approval for plans by the Executive Board.

As mentioned above, some argue that FP&A is or should be included in the process as well. The terms supply chain management or supply chain planning are also often used when referring to the process of sales and operations planning.

Originally, the term Production Planning was used to describe what is now known under S&OP.

The process of S&OP

Every planning process has one key requirement – data. It must be available in a structured and consistent way and, ideally, be of high quality. This means that it shouldn’t be incomplete or have extreme values (outliers). The means the first step is accessing and preparing data.

What follows are tightly integrated steps which are continually measured in terms of performance. After data preparation comes demand planning, where planners need to constantly compare sales actuals vs. sales forecasts vs. plans. To align with marketing, these should also be synced to marketing plans for demand generation.

Next is supply planning where the question on how to meet demand should be answered. For this, production actuals are constantly compared to plan. Rated capacity as well as workforce capacity plays a big role here, which is why it is important to also have protocols in place to handle unforeseen shortages in supply due to production outages.

In the next step, supply and demand planning for all regions is consolidated and then balanced to be in sync. The goal is to validate planning from the preceding steps and aggregate it. This is also the step where Financial Planning & Analysis plays into the process.

For the last step in the continuous cycle, Executive S&OP, actuals and plans are compared again on aggregate level and plans for exceptions are made. This is also the step in which potential issues must be discussed and eliminated. The frequency of the planning cycle highly depends on industry and produced goods and can range from weekly to monthly or quarterly.

The scale of S&OP can also vary significantly and ranges from country level, to regional (e.g., EMEA, Americas etc.), to global. The bigger the picture, the more complex are consolidation processes. For global sales and operations planning with short planning cycles, a S&OP solution as a planning platform is virtually inevitable.

Strengthening accuracy and collaboration in S&OP

Sales and operations planning is a complex process, and the planning cycles are typically shorter rather than longer. Starting from data preparation, for which many companies are already using a data warehouse that ensures consistency from sales plans and forecasts to demand and supply planning, S&OP software can be beneficial.

While many organizations already use some form of planning software, they’re often challenged by fragmented systems resulting in data silos and, therefore, inconsistent data. With platform solutions with integrated databases as a single source of truth, planning becomes unified, consistent, and collaboration strengthened. This ensures higher data quality and planning accuracy.

The problem with data silos in the planning process

In many manufacturing companies, large and small, sales reps and leaders regularly consolidate their data in a central spreadsheet. The sales data must then be enriched with master data from the ERP to implement sales and production planning. This is a tedious and lengthy process, in which often only monthly data is available instead of daily data because it takes so long. Due to the repetitive and tiresome tasks of getting the data to the spreadsheets, errors often occur when copying and pasting the data.

The underlying problem is the retention of data in the various source systems, which effectively act as data silos. Sales relies on CRM systems such as Salesforce, production relies on an ERP, and purchasing relies on a procurement solution. Accounting and marketing often use their own specialized systems as well, oftentimes even different ones in the various regions of operation. The data for a coherent overall picture and a 360° overview are there, but not connected.

For planning purposes, dozens of exported Excel spreadsheets have to be collected, reconciled and merged each time. This not only costs everyone involved time and nerves, but also means that the data is no longer up to date, once leaving the source systems through an export.

Breaking up and preventing data silos

The problems caused by data silos are clear: sales and operations planning takes too long, plans are inaccurate, not very up-to-date, and difficult to adapt. Controllers from Finance and other departments as well as supply chain managers are doing themselves as well as the organization a favor by fixing the silo problem.

That’s why some companies are using solutions that incorporate and unify all relevant data. Ideally, they are also automatically processed via ETL (Extract, Transform, Load). The central databases serve as a single source of truth.

In order to get rid of data silos in the long term, it is valuable to talk with the managers in the different departments. If they introduce a new software solution for a specific problem, data integration is often forgotten in that process. Educate your colleagues about the importance of integrating data. Their teams will also benefit from not having to deal with data exports on a regular basis.

Combining a single source of truth and planning

A data warehouse is an important first step to enable Finance, Sales, and production planners to work more collaboratively based on the same data. But when it comes to planning, multiple new Excel spreadsheets are quickly created. To avoid this issue, modern S&OP software provide the capability to unify your database, planning, and analysis solutions.

This has the advantage that the data can also be edited directly and the effects of new figures on plans and forecasts are immediately visible. New spreadsheet chaos is prevented and new isolated applications in specialist departments are avoided. All performance management happens with a single unified solution.

The complexity of the data of hundreds or even thousands of products along the supply chain thus becomes transparent to all stakeholders. Important links between sales, production and purchasing can be uncovered and identified. This also makes it easier to plan and coordinate the constantly changing demand for employees, machines, and parts.

Harmonizing and automating processes in this way also offers many advantages for sales forecasting and capacity planning at production sites. If all data is available uniformly, consistently, and centrally, reports and forecasts are easily automated. This means that all departments are always informed about the current situation and can adjust their sub-plans accordingly, if necessary. A unified S&OP solution for everyone ensures that the effects are always reflected in the other subplans and the top-level plan as well. Instead of having a multitude of different measurement standards, the most important KPIs can be defined consistently for everyone across the organization and resolve the data silo problem.

The benefits of Platform as a Service (PaaS) for S&OP

- Collection, preparation, consolidation, and aggregation of data is faster and more accurate than with multiple Excel spreadsheets or a fragmented system environment

- Data consistency and quality is ensured through one SSOT, providing always up-to-date information to everyone across the organization, therefore supporting better collaboration

- Comparing actuals to forecasts and plan is faster and forecasts are easily adjusted

- Finance and sales planning with a tool that is independent from your ERP but seamlessly connects to it and has write-back capabilities makes sure that everything runs smoothly

- Easily run scenarios based on one variable model to forecast and plan for price changes of raw materials, changing demand, and competitive pricing.

To learn more about how to boost S&OP decision-making watch our on-demand webinar.